The rapid evolution of battery technology is at the forefront of the electric vehicle (EV) revolution. As automotive manufacturers and researchers strive to improve the efficiency and sustainability of cars, innovative systems are being developed to enhance battery performance, longevity, and charging capabilities. These advancements are critical to addressing the increasing demand for cleaner transportation options and mitigating the environmental impact of traditional fuel-powered vehicles.

Recent breakthroughs in battery chemistry, such as the introduction of solid-state batteries and the application of lithium-sulfur technology, promise to significantly increase energy density, allowing EVs to travel longer distances on a single charge. Furthermore, researchers are exploring alternatives to cobalt in battery production, which not only improves resource sustainability but also reduces costs. These innovations are transforming how battery systems are designed and integrated into electric cars, paving the way for a new era of efficient and eco-friendly transportation.

In addition to improving the performance characteristics of electric vehicle batteries, advancements in regenerative braking systems and fast charging technology are enhancing the overall user experience. These innovations are essential for alleviating range anxiety and making electric cars more appealing to a wider audience. As the automotive industry continues to embrace these cutting-edge technologies, the transition to electric mobility is set to accelerate, leading to a cleaner, more sustainable future for all.

Advancements in Lithium-Ion Chemistry for Enhanced Range

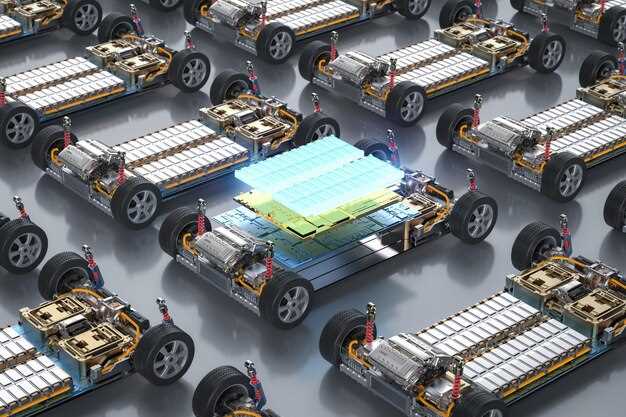

The pursuit of longer ranges for electric vehicles has spurred significant advancements in lithium-ion chemistry. Innovations in battery materials and designs aim to improve energy density, charging speed, and overall performance. Key developments include the incorporation of silicon anodes, which can store more lithium ions compared to traditional graphite anodes. This enhancement leads to a substantial increase in the battery’s capacity, allowing electric cars to travel greater distances on a single charge.

Another promising approach involves the use of solid-state electrolytes, which replace conventional liquid electrolytes. Solid-state batteries not only improve safety by reducing flammability risks but also enable higher energy density. This transition is crucial as manufacturers strive to create systems that can sustain longer ranges while maintaining efficient charging cycles.

Moreover, advancements in cathode materials, including nickel-rich formulations, have shown potential for increased voltage and energy retention. By optimizing the composition of these components, engineers enhance the overall efficiency of the battery, translating directly into better performance for electric cars.

In addition to material enhancements, innovative thermal management systems are being developed to maintain optimal operating temperatures. Effective thermal regulation ensures that batteries perform efficiently, maximizing range and longevity while preventing the degradation often associated with high heat.

Overall, the combination of improved materials, advanced chemistries, and optimized systems is pivotal for the next generation of lithium-ion batteries. These advancements not only extend the driving range of electric vehicles but also contribute to the broader adoption of sustainable transportation solutions.

Solid-State Batteries: Potential for Safety and Performance Gains

Solid-state batteries represent a significant leap forward in electric vehicle technology. Unlike traditional lithium-ion systems, which utilize liquid electrolytes, solid-state batteries employ solid electrolytes. This fundamental change drastically enhances safety by reducing the risk of leaks and fires, common concerns associated with conventional batteries.

One of the primary advantages of solid-state systems is their potential for increased energy density. These batteries can store more energy in a smaller volume, translating into longer driving ranges for electric cars. This capability is critical for addressing one of the key challenges facing the electric vehicle market today: range anxiety among consumers.

Moreover, solid-state batteries offer improved performance in extreme temperatures. While traditional batteries tend to experience diminished performance in cold or hot conditions, solid-state technology can maintain stability, ensuring reliability in various environments. This reliability is vital for electric cars, which are becoming more integrated into everyday life.

Additionally, the durability of solid-state systems promises longer life cycles. With less degradation over time compared to their liquid counterparts, these batteries could reduce the frequency of replacements and lower overall ownership costs for electric vehicle users.

In summary, solid-state batteries present a revolutionary opportunity for enhancing both safety and performance in electric vehicles. By addressing current limitations of existing battery technologies, they hold the potential to accelerate the adoption of electric cars and contribute to a more sustainable transportation future.

Recycling Techniques for Sustainable Battery Life Cycle Management

As electric vehicle adoption accelerates, the importance of effective battery recycling techniques becomes paramount. Sustainable battery life cycle management not only reduces environmental impact but also recovers valuable materials for future systems. Various innovative recycling methods are being developed to enhance the performance and longevity of battery systems.

Hydrometallurgical recycling is one of the most promising techniques. This process involves using aqueous solutions to leach metals from spent batteries. By selectively dissolving components, it efficiently extracts metals such as lithium, cobalt, and nickel, which can be reused in new battery production, significantly minimizing the need for virgin materials.

Pyrone-based extraction has emerged as an efficient method as well. This involves the use of organic solvents that selectively bind to valuable metals. The result is a streamlined process that not only recovers materials but also reduces waste and energy requirements typically associated with traditional methods.

Moreover, thermal treatment methods also play a crucial role in battery recycling. In this approach, batteries are subjected to high temperatures, which facilitate the breakdown of organic components while recovering metals in a concentrated form. This technique can be optimized for different battery chemistries, enhancing overall efficiency.

Additionally, advancements in direct recycling techniques focus on reusing components without complete disassembly. This method aims to preserve the structure of electrode materials, allowing for lower energy consumption and minimizing resources wasted in the recycling process. Such practices underline the need for developing batteries designed with recycling in mind.

To optimize battery life cycle management, the collaboration between manufacturers, researchers, and policymakers is crucial. Implementing standardized recycling protocols will ensure that valuable materials are effectively recovered while promoting responsible disposal practices. Prioritizing these innovative recycling techniques not only supports sustainable battery production but also contributes to the circular economy of electric vehicle technologies.